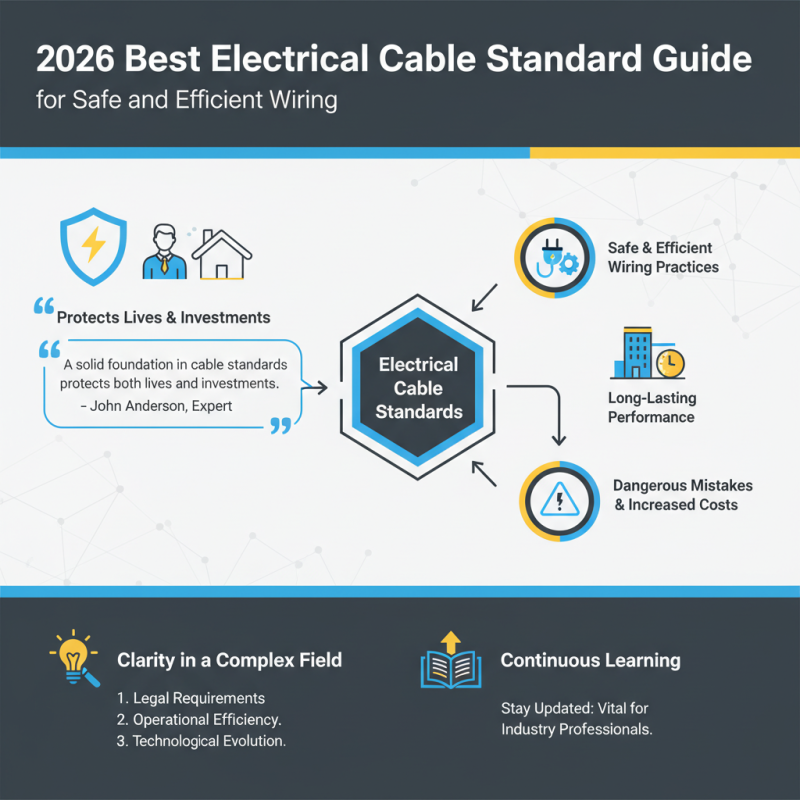

In the realm of electrical engineering, adhering to Electrical Cable Standards is crucial. Expert John Anderson emphasizes, "A solid foundation in cable standards protects both lives and investments." These standards guide safe and efficient wiring practices, essential in today’s technology-driven world.

The 2026 Best Electrical Cable Standard Guide aims to bring clarity to a complex field. Each standard serves a specific purpose, yet many professionals overlook them. This negligence can lead to dangerous mistakes and increased costs.

Wiring systems should not only meet legal requirements but also provide long-lasting performance. Ignoring the nuances of Electrical Cable Standards can result in operational inefficiencies. As technology evolves, continuous learning is vital for industry professionals.

In 2026, understanding electrical cable standards will be crucial for safety and efficiency. Industry reports predict that improper wiring contributes to 30% of electrical fires. This statistic highlights the importance of adhering to established guidelines. Electrical cables must meet specific criteria, including insulation material and temperature ratings. Compliance ensures not only safety but also optimal performance in various applications.

The National Electrical Code (NEC) and International Electrotechnical Commission (IEC) are key regulatory bodies. They refine standards regularly to reflect advancements in technology. In recent years, the push for sustainability has led to innovations in cable manufacturing, such as reducing carbon footprints. Yet, challenges remain. Many professionals still overlook these standards, leading to inconsistent installations and potential hazards.

Additionally, awareness among electricians about evolving regulations is lacking. Training programs often do not cover the latest updates. This gap leaves room for mistakes. As new materials and technologies emerge, staying informed is essential. The industry must prioritize education to enhance safety. Regular updates to training resources could bridge this knowledge gap and foster a safer wiring environment.

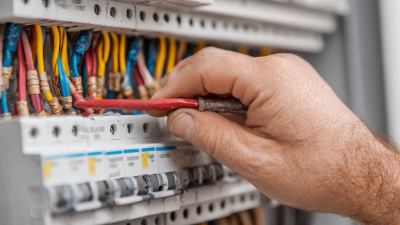

When it comes to electrical wiring, safety should always be a priority. Proper installation reduces risks. Whether at home or in a commercial space, avoid shortcuts. Each cable type has specific ratings and applications. Selecting the wrong type can lead to overheating or electrical fires.

Consider insulation ratings carefully. They determine how much temperature the cable can withstand. Using cables unsuitable for high temperatures can be dangerous. Always check for wear and tear before starting a project. Damaged wires can cause short circuits. It's easy to overlook these signs in a hurry.

Understanding local codes is essential. Compliance ensures safety and functionality. Many people assume misinformation without checking. Each region may have different regulations regarding material use. Be proactive in consulting resources and experts. Mistakes can be costly, not just in terms of money but also safety. The consequences may last long beyond the installation.

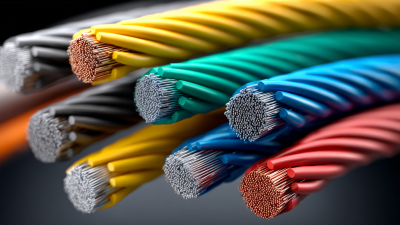

When selecting electrical cables, understanding different types is crucial for safety and efficiency. There are various cable types, each tailored for specific applications. The most common variants include THHN, NM-B, and UF cables.

THHN is used mainly for building wiring. It can withstand heat and resist moisture, making it a versatile choice. NM-B, or non-metallic sheathed cable, is typically used for residential wiring indoors. Its affordability and ease of use make it popular among homeowners.

Another key type is UF cable, designed for outdoor use. This cable is resistant to moisture and can be buried underground. According to the National Electrical Manufacturers Association, over 80% of residential wiring utilizes NM-B cables. However, misusing or improperly installing cables like these can lead to significant risks. Many installations fail due to poor choices.

Data from the Institute of Electrical and Electronics Engineers highlights that improper cable selection accounts for over 30% of electrical failures in homes. It's essential to choose cables wisely based on their intended use. Understanding these differences can help avoid costly errors and ensure safe electrical systems in both homes and businesses.

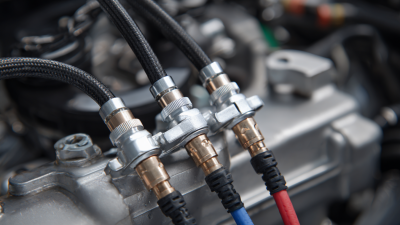

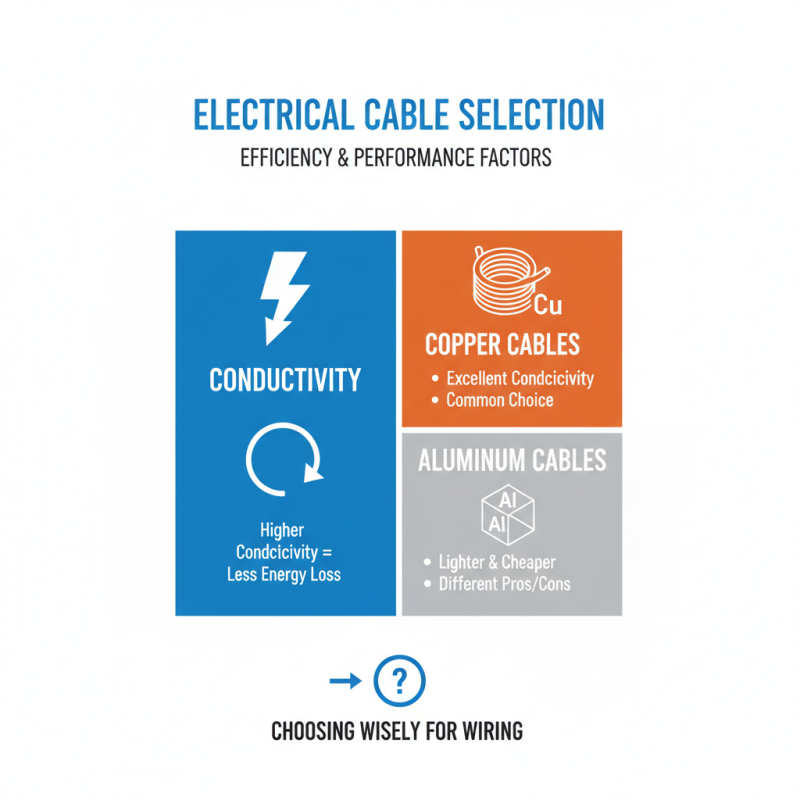

When selecting electrical cables, various factors influence efficiency and performance. Conductivity is crucial. A higher conductivity reduces energy loss during transmission. However, the material choice can complicate decisions. Copper is common for its excellent conductivity, while aluminum is lighter and often cheaper. Both materials have unique pros and cons, which can affect wiring projects differently.

Insulation type also plays a significant role. It protects against heat and environmental factors. Proper insulation ensures safety but can be overlooked in cost-cutting measures. Inadequate insulation can lead to overheating, posing serious hazards. Striking a balance between cost efficiency and safety is essential but often challenging.

Cable length impacts voltage drop. Longer cables can lead to greater energy loss, and this shouldn't be ignored. Calculating the right length to avoid performance issues matters. Often, installers underestimate this factor. Understanding these elements shapes effective wiring choices, promoting safer, more efficient electrical systems.

The electrical cable manufacturing industry is evolving rapidly. As we look towards 2026, several trends are emerging that shape the future of standards and safety. A report from the International Electrotechnical Commission (IEC) indicates that the use of more sustainable materials will rise. Yet, many manufacturers still rely on outdated practices. These traditional methods often lead to inefficiencies and waste.

Moreover, innovations like IoT integration in electrical cables are gaining traction. This technology can enhance real-time monitoring of electrical systems. However, not all manufacturers are equipped to implement such technologies. Industry research shows that only 25% of companies have adapted to these advancements. This gap highlights a significant area for improvement.

Moreover, compliance with evolving standards remains a challenge. The latest data suggests that about 40% of manufacturers face difficulties in keeping pace with regulatory changes. This non-compliance can pose safety risks. Industries must find ways to bridge this gap. Addressing these issues is critical to ensuring that electrical cables are both safe and efficient. The journey ahead is fraught with challenges, yet it also offers significant opportunities for innovation.